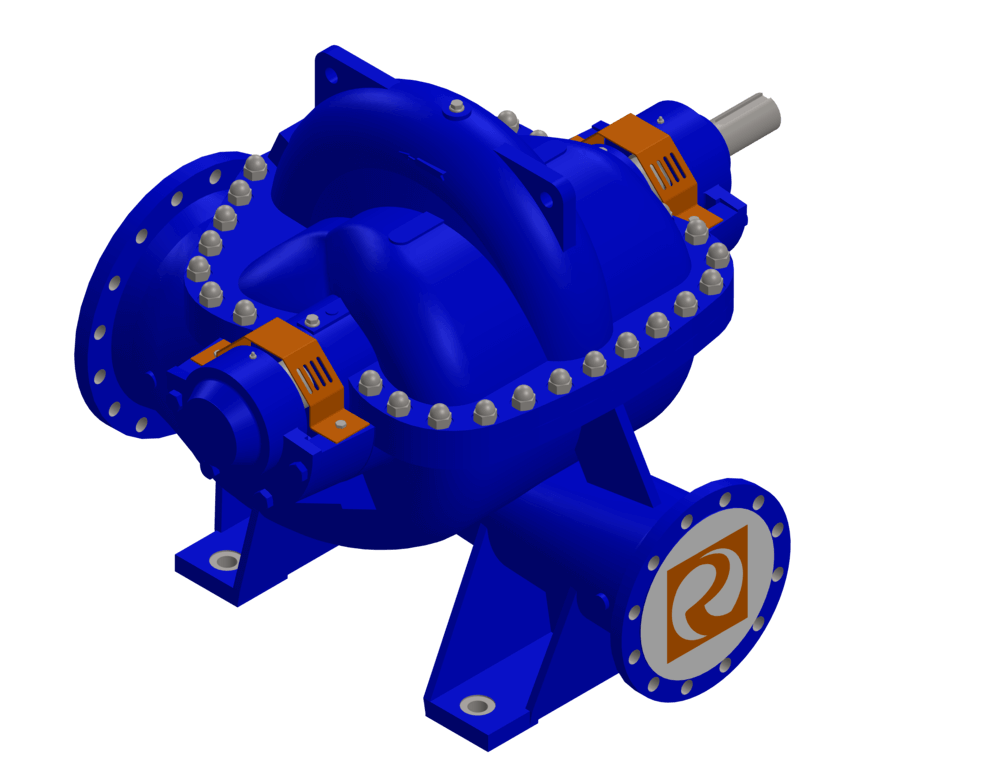

Dual flow pump CD1

Horizontal, axially split single-stage pump with a radial dual-flow impeller. Bearings lubricated with grease. Seal chamber designed for installation of compressed seals, mechanical seals, folded or cassette structures, including the installation of a double seal.

ISO 5199, EU directive ATEX 2014/34/EU

Technical specfications

Q max = 7500 m3/h

H max = 190 m

T max = 80 °C

Application

Pumps are used in chemical and petrochemical plants and power plant’s cooling systems. Drinking and service water networks. Installations of fire systems and irrigation stations. Vertical design can be used to reduce space requirements.

Modification

Vertical design with one seal

Impeller with overlapped blades

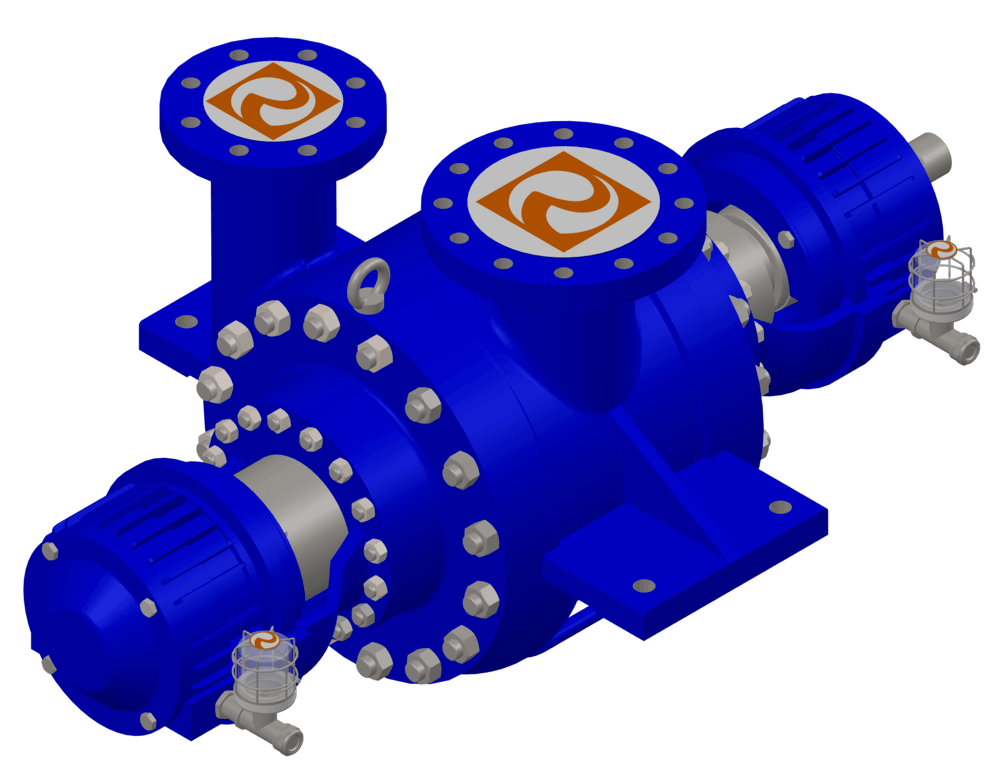

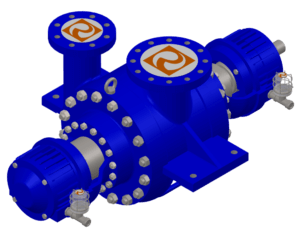

Dual flow pump CD2

Horizontal, radially split single-stage pump or two-stage pump with radial impeller. Between bearing version. Pump design is in accordance with API 610-BB2. Bearings are lubricated with oil bath. Seal chamber designed for the installation of mechanical cassette seals according to API 682. Bearing bracket are equipped with ribs for intensifying heat transfer.

API 610/ISO 13709, EU directive ATEX 2014/34/EU

Technical specfications

Q max = 1750 m3/h

H max = 300 m

T max = 450 °C

Application

Pumps are used in the most demanding chemical and petrochemical plants and in power plants. It is a typical pump for use in cracking systems. Designed for high temperature media up to 450 °C.

Modification

Additional fan/ventilator for the bearing console

Cooled / heated seal chamber

Cooled / heated casing of the bearing console

External lubrication systém