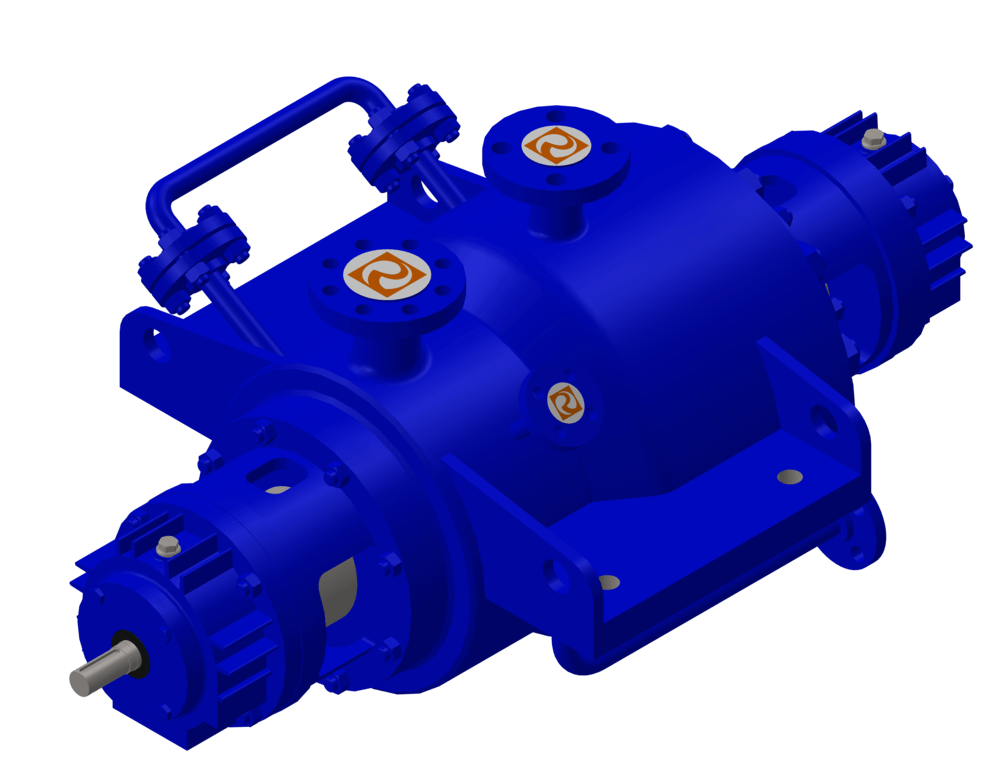

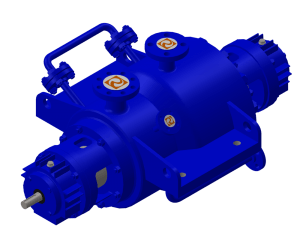

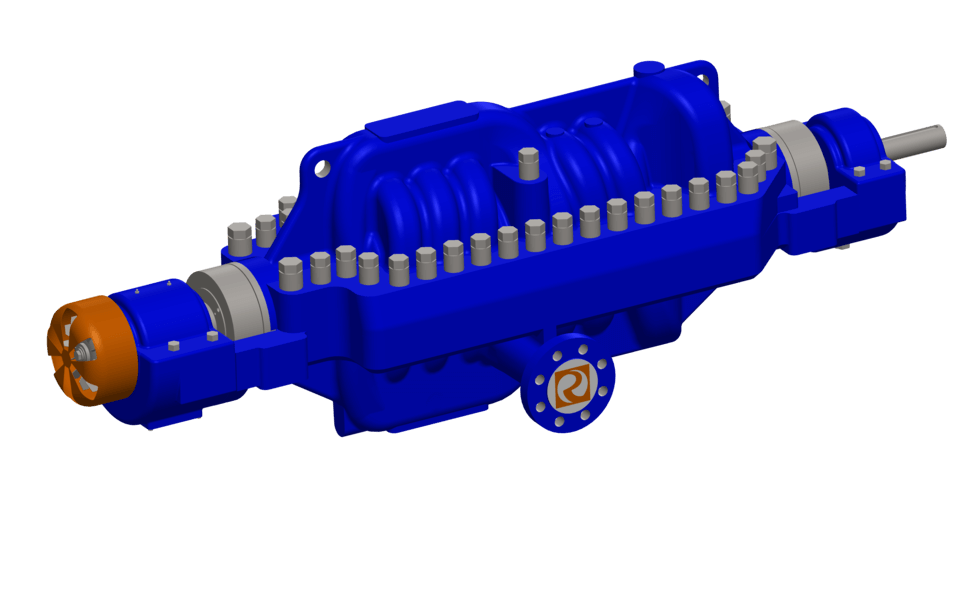

Multistage pumps CM3

Horizontal, axially split multistage pump with radial impellers. Between bearing version. Cantilever design with pump in shaft axis. Pump design is in accordance with API 610-BB3. Combination of bearings, sliding pan for radial reaction and compensating rolling bearing for capturing residual axial force, lubricated with oil bath. The position of the impellers on the rotor assembly reduces the resulting axial force to a minimum. Seal chamber is designed for the installation of mechanical cassette seals according to API 682. Bearing bracket is equipped with ribs for intensifying heat transfer.

API 610/ISO 13709, EU directive ATEX 2014/34/EU

Technical specfications

Q max = 1680 m3/h

H max = 1000 m

T max = 200 °C

Application

Pumps are used in demanding chemical and petrochemical plants and power plants. It is a typical pump found in systems for supplying and transporting petroleum products and in cracking systems. Used in power blocks as power pumps and as injection pumps for oil fields. Designed for high pressure systems, maximum transport height (head) up to 800 m. Suitable for media with temperatures up to 250 °C.

Modification

Additional fan/ventilator for the bearing console

Cooled / heated seal chamber

Cooled / heated casing of the bearing console

External lubrication system

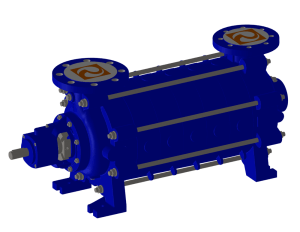

Multistage pumps CM4

Vertical, radially split single-stage pump with axial inlet and radial impeller for installation in wet sumps. Pump design is in accordance with API 610-VS4. Bearings are lubricated with grease. Seal chamber designed for the installation of mechanical cassette seals according to API 682. Guide shaft sleeves are lubricated with a pumped medium.

API 610/ISO 13709, EU directive ATEX 2014/34/EU

Technical specfications

Q max = 1250 m3/h

H max = 500 m

T max = 200 °C

Application

Pump are used in chemical and petrochemical plants, power plants, as well as for transporting water and contaminated water. They are part of the installations in closed tanks or open sumps. Widely used in cracking systems, for pumping of the process residues and waste products. Used for pumping aggressive media.

Modification

External flushing / lubrication of guide sleeves

Heated structure

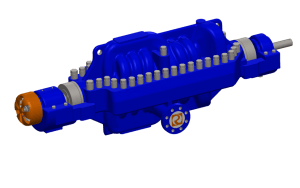

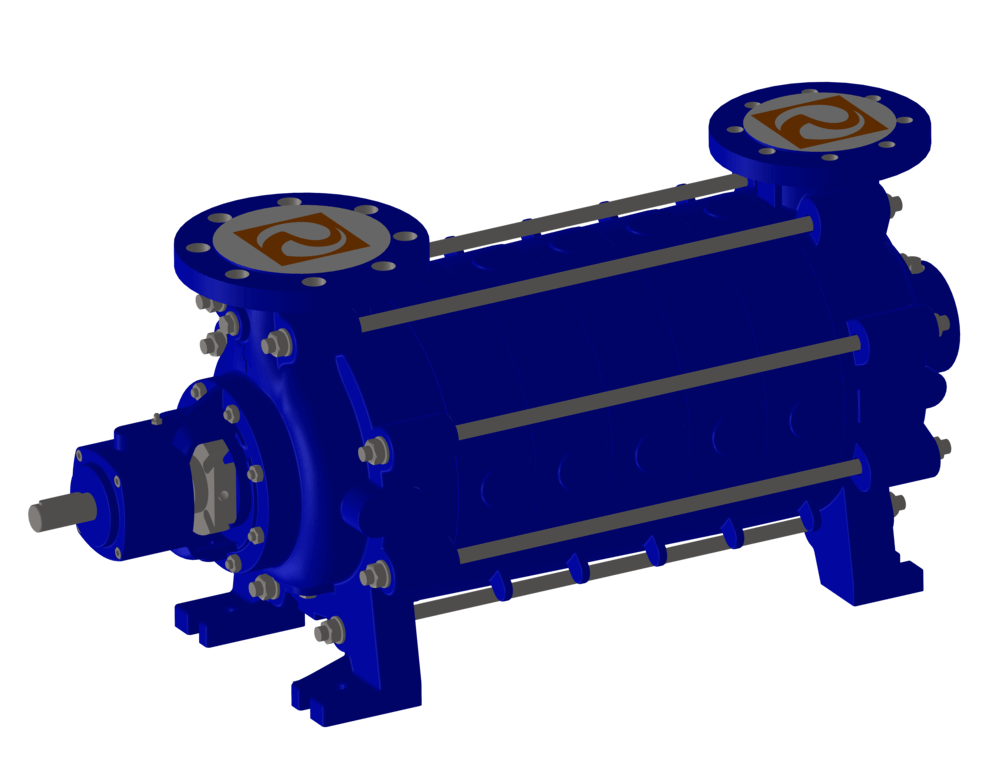

Multistage pumps CM5

Horizontal, radially split segmental pump with radial impellers, barrel type formation. Between bearing version. Cantilever design with pump in the shaft axis. Pump design in accordance with API 610-BB5. Combination of bearings, sliding pan for radial reaction and compensating rolling bearing for capturing residual axial force, lubricated in with oil bath. Pumps of smaller power parameters only fitted with rolling bearings. The axial force on the bearing is reduced by the balance disk behind the last degree. Seal chamber designed for the installation of mechanical cassette seals according to API 682. Bearing bracket equipped with ribs for intensifying heat transfer.

API 610/ISO 13709 or ISO 5199, EU directive ATEX 2014/34/EU

Technical specfications

Q max = 1250 m3/h

H max = 1500 m

T max = 480 °C

Application

Pumps are used in demanding chemical and petrochemical plants and power plants. It is a typical pump to be found in systems for supplying and transporting hot petroleum products and in cracking systems. Used in power blocks as power pumps. Designed for high pressure systems, maximum transport height (head) up to 1,500 m. For transporting high temperature media, up to 480 °C.

Modification

Additional fan/ventilator for the bearing console

Cooled / heated seal chamber

Cooled / heated casing of the bearing console

External lubrication system